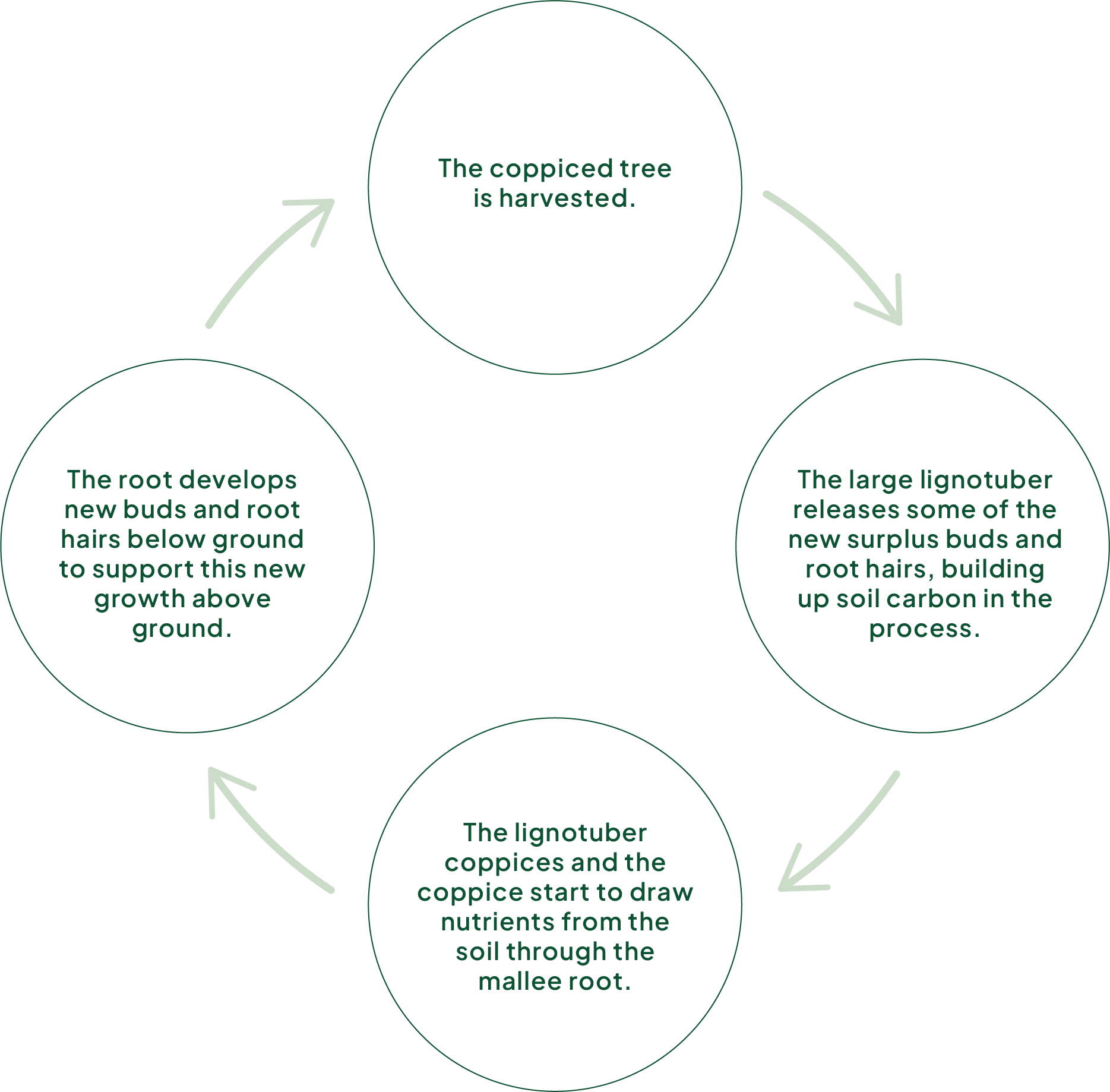

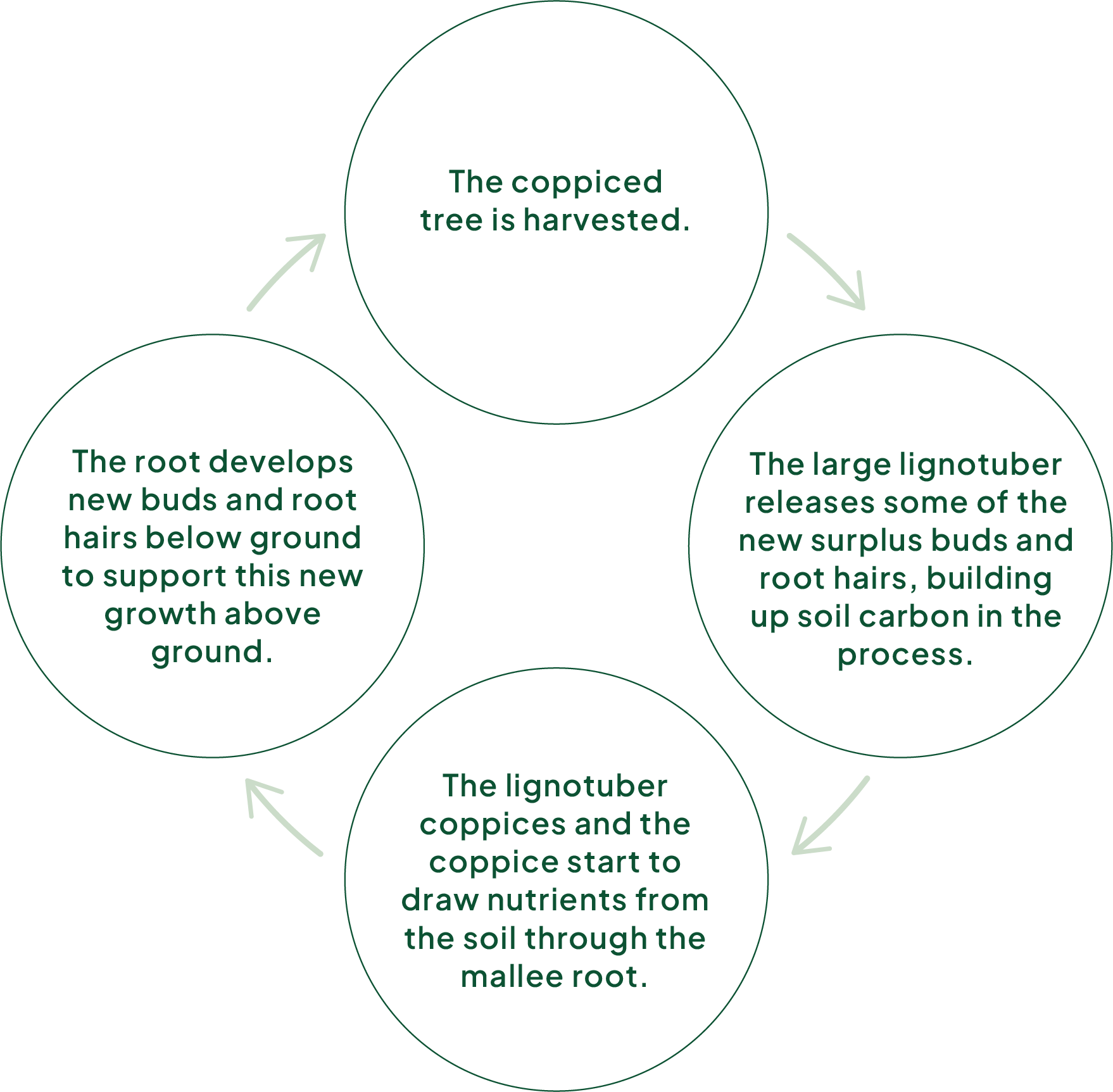

Our plantation management includes planting new seedlings to expand our plantations, harvesting mature trees, coppicing (to produce regenerative growth, increased biomass and multiple trunk development) and processing the harvested plant biomass.

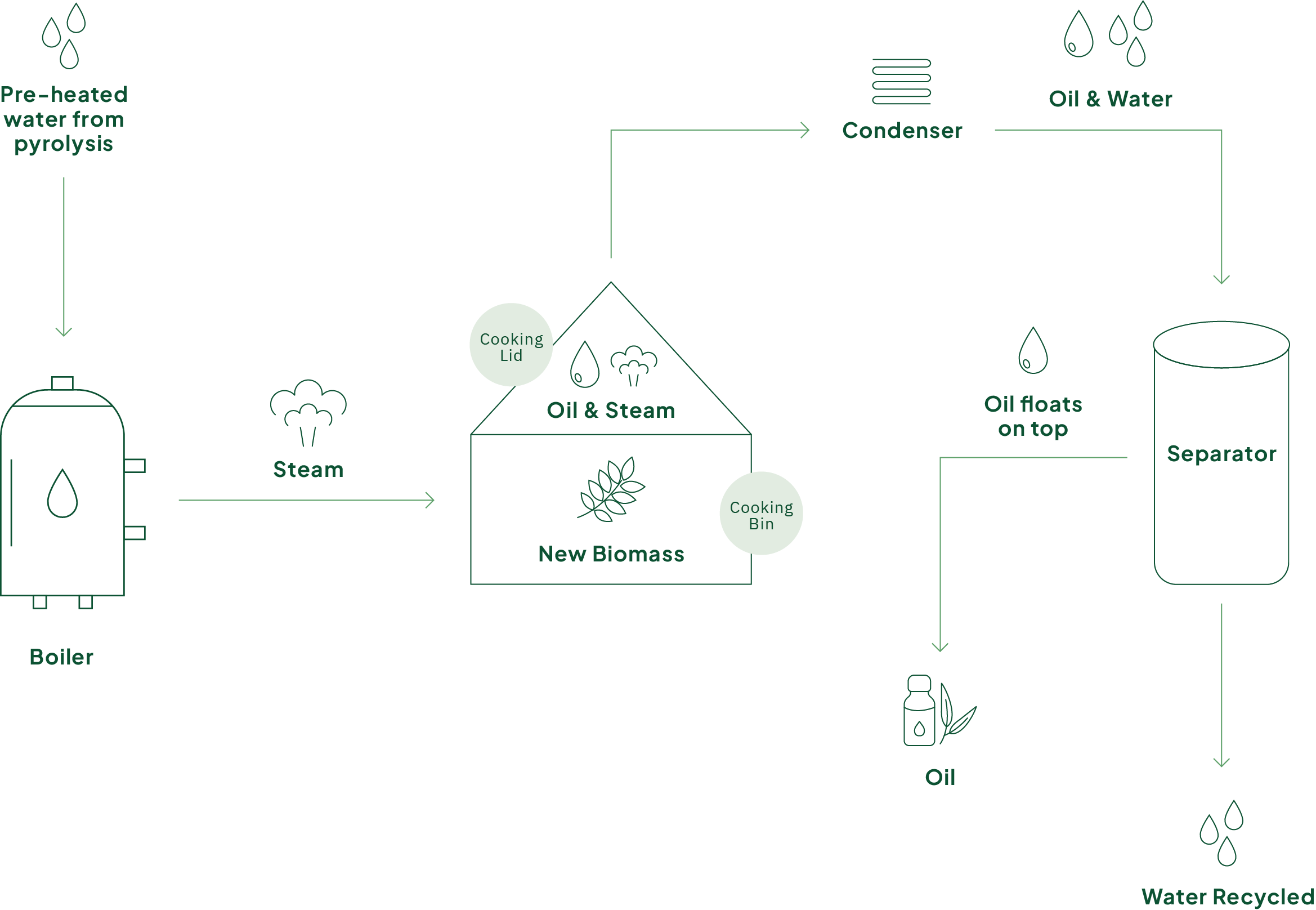

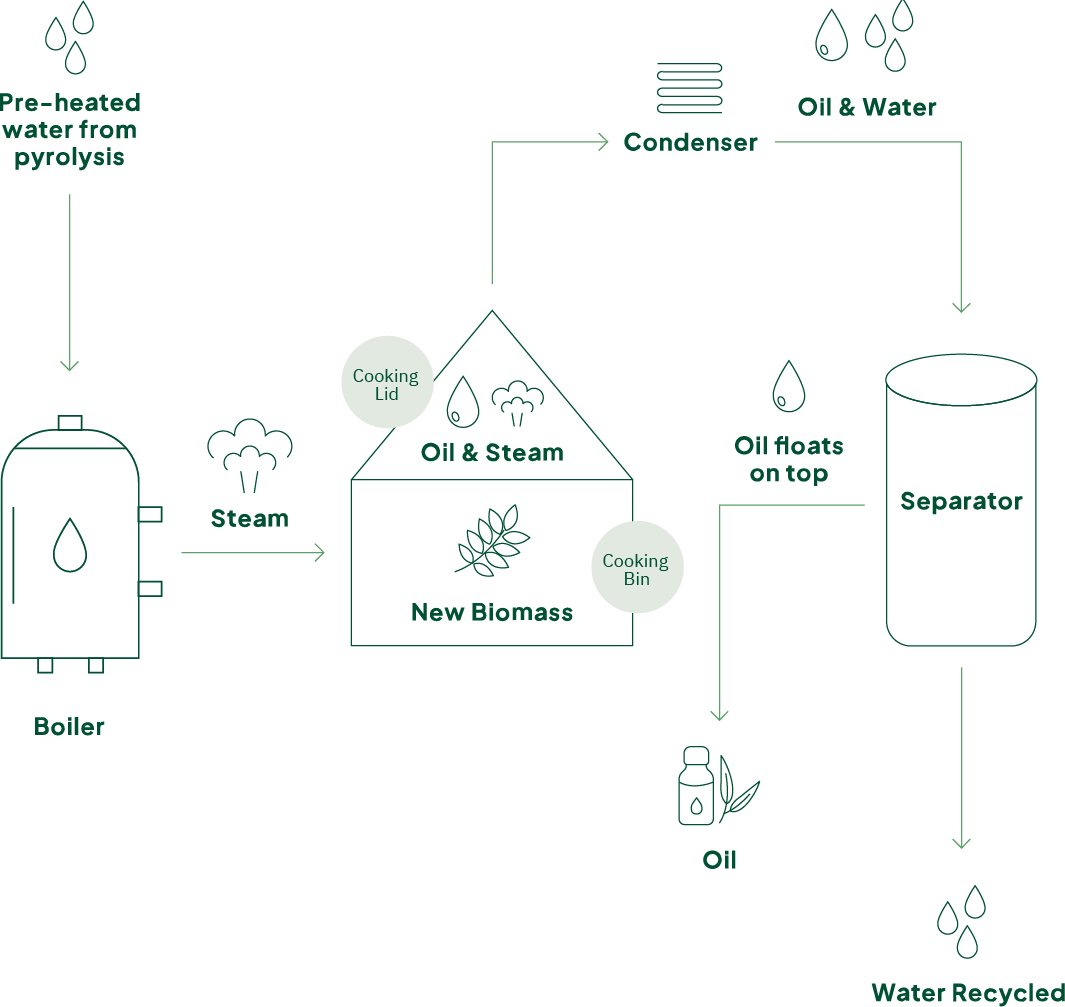

Biomass processing by steam distillation, pyrolysis and condensation generates our value-added and environmentally sustainable product range, including high cineole-content eucalyptus oil, biochar and wood vinegar. We also produce Australian Carbon Credit Units (ACCUs) and CO2 Offset Certificates (CORCs) for sale through the growth, harvest and processing cycle of our mallee and other eucalypt plantations. Our plantations also provide significant environmental benefits by reducing soil and wind erosion; re-establishing natural ecosystems/habitat; and reducing water table levels and soil/water salinity.

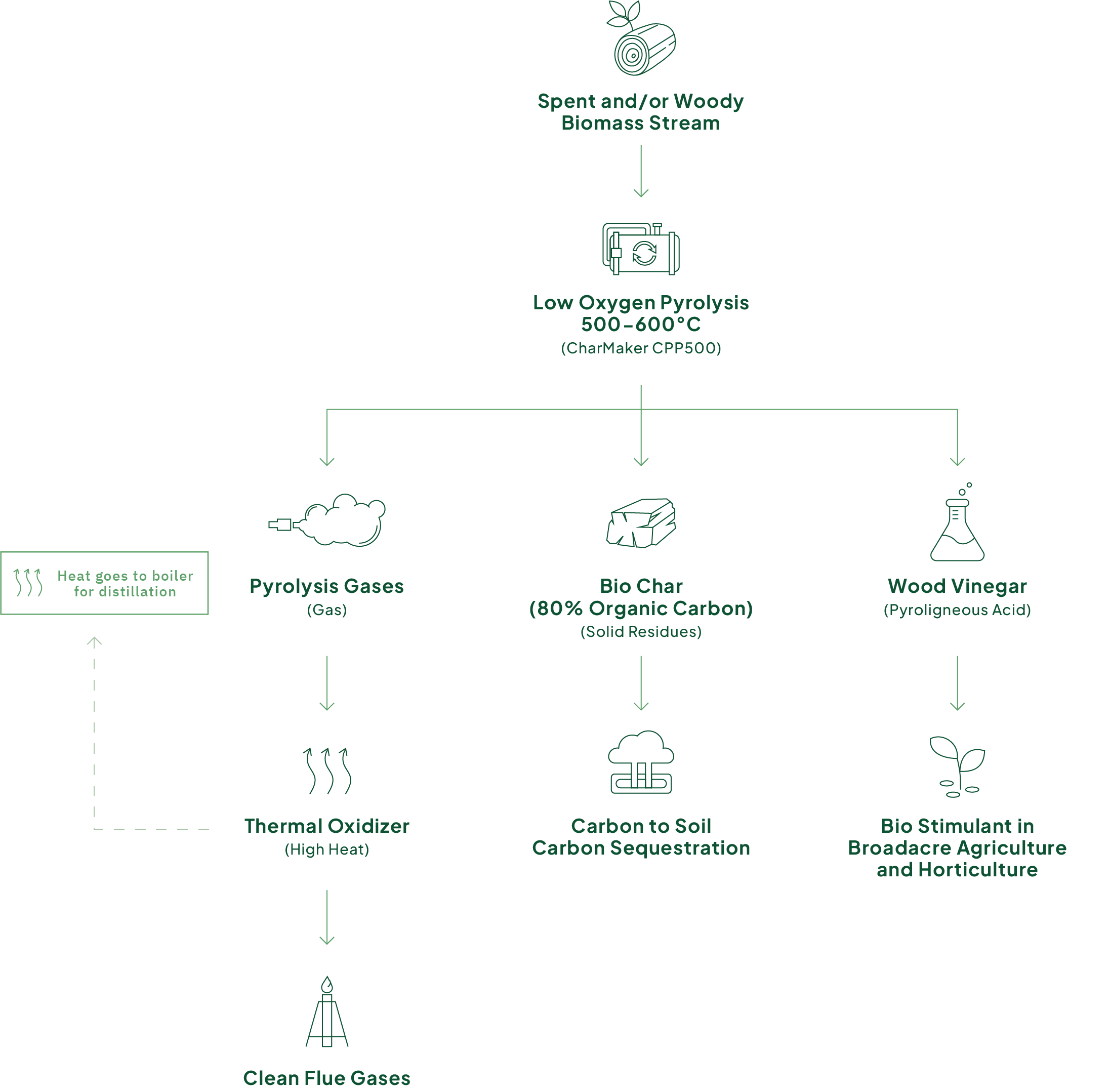

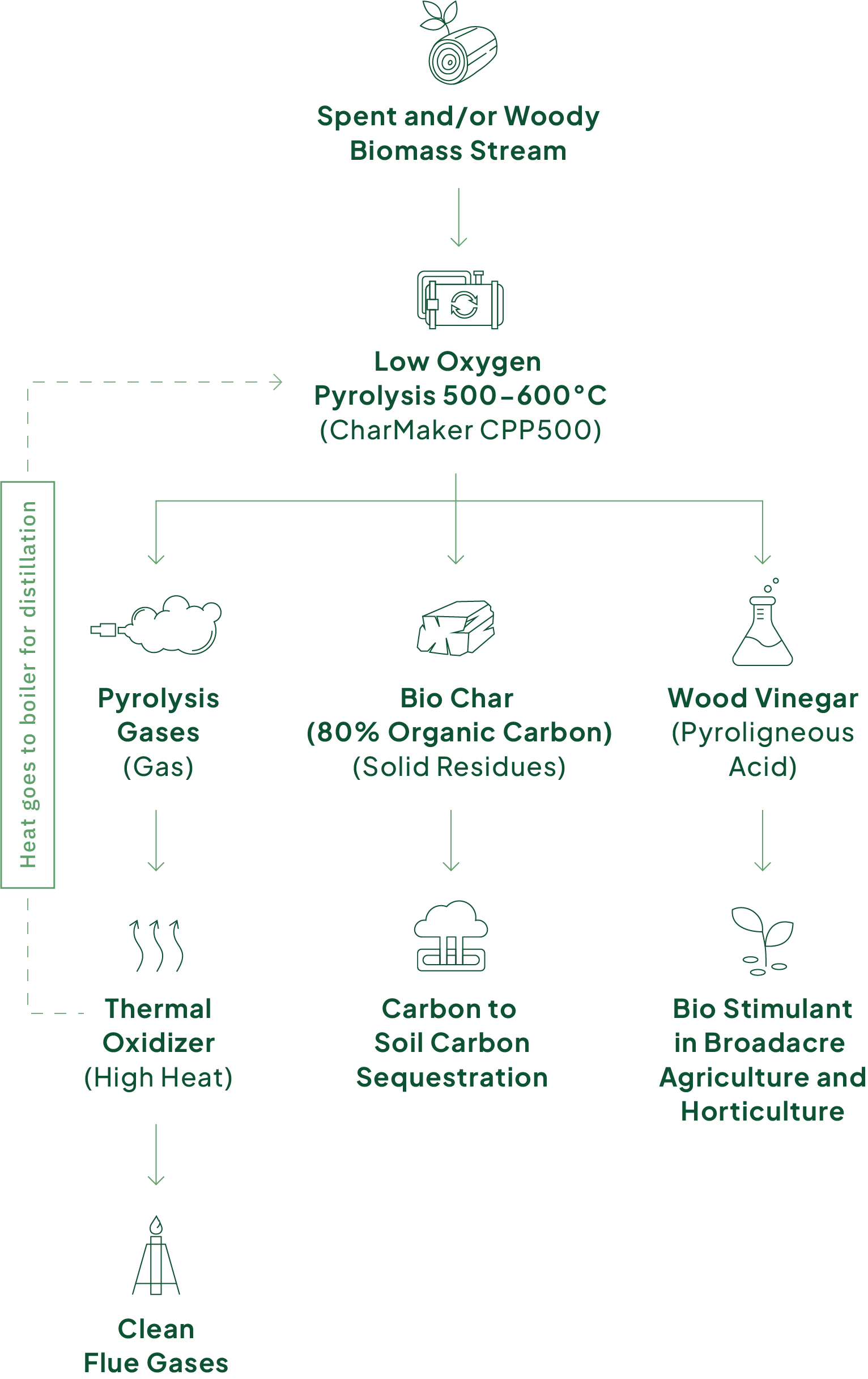

Pyrolysis

Pyrolysis is the thermal decomposition - or burning/charring - of mallee tree biomass at high temperatures in an inert and relatively anaerobic, or oxygen-free environment. Spent plant biomass - biomass left over from the steam distillation process to produce oil and biomass from the trunk and branches of mature trees - is pyrolysed to produce a range of products.

ACCUs

(Carbon Credits)

Fasera produces Australian Carbon Credit Units, or ACCU’s - financial instruments awarded to eligible carbon projects by the Australian Government Clean Energy Regulator- from our registered plantations. We sell ACCUs to companies seeking to offset the carbon emissions that they cannot reduce.

How they fit together

The Full-Circle Process

If you’re an investor, farmer or wholesale purchaser and would like to stay informed about our current and planned future projects, please subscribe to our newsletter.